What's water jet cutting?

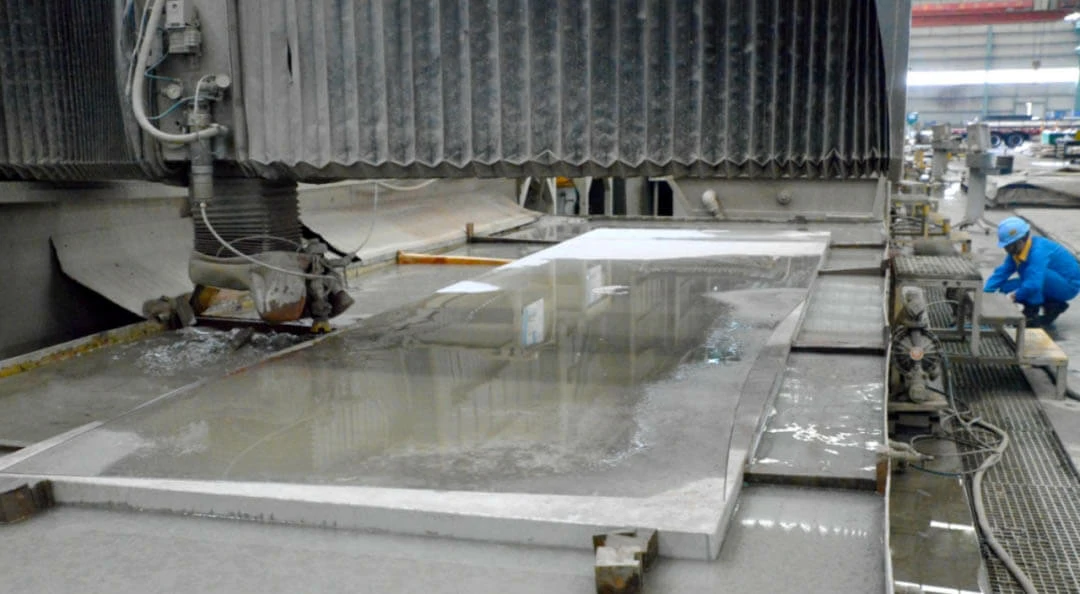

Water jet cutting is a manufacturing process that uses high-pressure jets of water provided by pressurizing pumps that deliver a supersonic stream of water to cut and shape various types of materials.

The water jet-cutting process can be completed in several different ways. The majority of the methods have an abrasive blended into the water to cut particles from the workpiece. It is a very versatile manufacturing process that can be used to cut, shape, and design a workpiece to meet exact specifications.

The shaping method used for water jet cutting has several advantages over other cutting processes, such as plasma or laser. Water jet cutting has better accuracy, can cut complex designs, and is able to cut thermally sensitive surfaces. The abrasive is like sandpaper and erodes the material being cut. It does not heat the material or changes its temper. The cut edges are clean and can be welded without the need for further processing.

We offer high-precision CNC waterjet cutting services for soft materials and sheet metals such as aluminum, steel, and copper. We provide on-demand manufacturing and can fabricate small and large series of parts. We have imported the most modern CNC waterjet cutter on the market, which makes it possible to deliver manufactured parts fast at affordable prices.

Advantages of our Waterjet Cutting:

- High accuracy

Waterjet cutting is known for providing high cutting accuracy. Waterjet cut parts are of very high quality even when limited by tight specifications.

A water jet cutting machine can work with tolerances up to 0.025 mm (0.001 inches) but tolerances between 0.075 to 0.125 mm are more common for parts less than one inch in thickness. The tolerances may increase with thicker materials depending on the technology. The accuracy depends on factors such as the table stability, machine construction, abrasive flow rate, cutting stream control, stream lag and process error. - No heat-affected zone

Heat-affected zone (HAZ) is a byproduct of most hot-cutting processes. In processes such as laser cutting and EDM, the zone around the cut edge does not melt during machining but undergoes a change in its properties.

Discoloration, heat distortion, and hardened edges can all affect the characteristics of the final part. These parts require heat treatment before being put into use.

Being a cold-cutting process, waterjet cutting does not create heat-affected zones. This gives the final parts superior edge quality and more dependable properties without imparting any stress to the part.

The use of water jet cutting thus diminishes the need to worry about imperfect cuts, weak points and warping. Manufacturers can also use pre-heat treated parts to bring down production costs.

Being a non-thermal cutting process also means that there is no slag formation and dross waste created. - High-quality finished parts

Waterjet cutting delivers superior quality parts that no other cutting method can compete with. The edges are smooth and do not need deburring.

The final quality depends on several factors such as cutting speed, pressure, abrasive flow rate and nozzle size. The process parameters may need to be modified for optimum output. - No need for tool changes

A waterjet cutter does not use any cutting tools and the nozzle does not need to be changed to accommodate different materials and thicknesses. The same nozzle is used for different applications by adjusting the cutting stream parameters, such as feed rate to achieve the appropriate cutting speed.

Since a tool change is not required between materials, the water jet cutting machine can cut different materials one after the other which improves the operational efficiency by saving time and tool costs. - Cost-effective process

Waterjet cutting is more cost-effective compared to alternative cutting methods in many applications, especially in the food industry. The process does not always need fixtures, jigs or clamps which increases the production speed.

Another benefit that this process offers is the possibility to stack and cut several layers of material all in one pass. Stacking can also be performed for dissimilar materials which makes this a simple yet effective way of increasing part production.

Cut parts also don’t require any post-processing which reduces the overall cost. The process also creates minimal material waste. - Compatibility with different materials

As explained before, the waterjet cutting process is not limited by the type of material. It can cut a wide range of materials as long as the correct process parameters and abrasives are selected. We shall cover this topic in detail further in the article. - Highly sustainable

In this day and age, sustainability is an important factor when selecting a manufacturing process. The waterjet-cutting process checks all the right boxes when it comes to sustainability. It has amazing advantages such as no slag formation, no dross waste and no need for heated parts. It also does not create any toxic fumes or greenhouse gases.

The finished parts also do not require any post-processing tasks such as heat treatment. The main cutting medium of water is also recyclable which reduces the impact on the environment. In addition, no cooling oils or lubricants are required as the water jet itself acts as a coolant.

Contact us at sales3@openex.com.cn or call us at +86 186 5928 0806 for more information about waterjet cutting or to receive a free project quote today.